Patient-specific 3D modeling is emerging as a powerful tool to improve surgical precision in complex cancer procedures. New research from The Ohio State University Comprehensive Cancer Center, Arthur G. James Cancer Hospital and Richard J. Solove Research Institute (OSUCCC–James) shows that using customized 3D-printed models during surgery leads to more complete tumor removal in patients with head and neck cancers that have invaded bone.

The study, recently published by OSUCCC–James, found that surgeons achieved clear, cancer-free margins in 92% of cases when patient-specific 3D models were used to guide the procedure. Achieving negative margins is critical in cancer surgery: removing all malignant tissue while preserving as much healthy tissue as possible directly affects both survival and long-term quality of life.

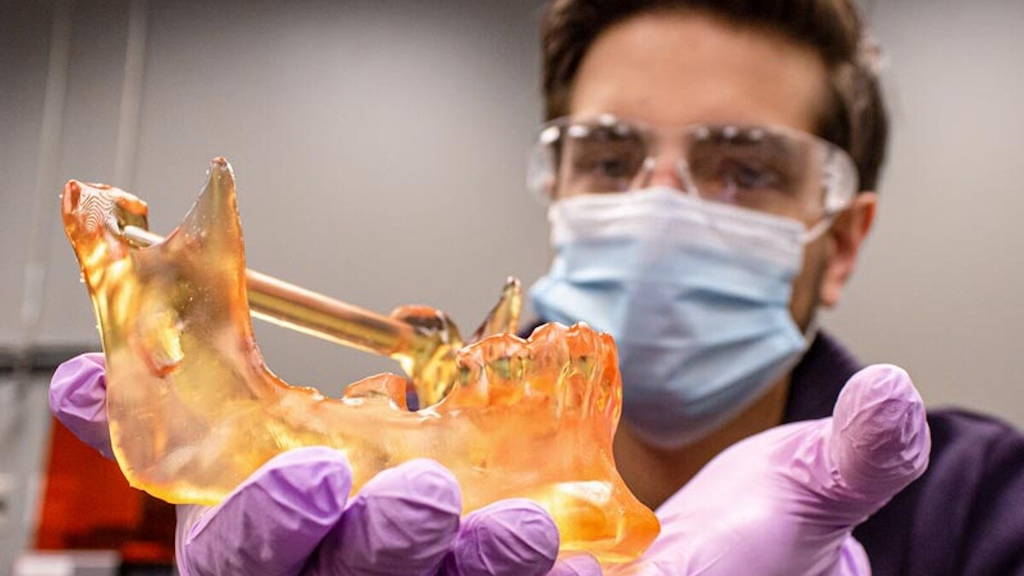

“Precision is everything in these surgeries,” says Kyle VanKoevering, MD, head and neck surgeon at OSUCCC–James and medical director of Ohio State’s M4 Lab (Medical Modeling, Materials and Manufacturing). “We need to remove the entire tumor, but avoid unnecessary damage to structures that are essential for speech, chewing and swallowing. Fully personalized 3D models give us a much clearer roadmap in the operating room.”

3D-guided surgery versus standard practice

The researchers compared outcomes in 68 patients treated for bone-invading head and neck cancers. In 37 cases, surgeons used in-house developed 3D models based on the patient’s imaging data during surgical planning and intraoperatively. The remaining 31 patients underwent standard surgery without this additional visual support. The patient population largely reflected the typical risk profile for this type of cancer: predominantly male, with nearly all patients having a history of tobacco use.

The difference was clear. Surgeries supported by 3D models more often resulted in negative surgical margins, indicating that no cancer cells were left behind in the surrounding tissue. This is particularly relevant for tumors that grow into bone, where tumor boundaries are difficult to see or feel during surgery.

“In bone-invading cancers, visual and tactile cues are limited,” VanKoevering explains. “By translating CT and MRI data into a tangible, patient-specific 3D model, we can better understand exactly where the tumor is and how it relates to critical anatomy. That allows us to be both more aggressive against the cancer and more conservative with healthy tissue.”

Digital planning meets surgical reality

The study highlights how digital technologies such as 3D modeling and printing are increasingly bridging the gap between preoperative imaging and real-time decision-making in the operating room. In head and neck oncology, this is especially valuable due to the density of vital structures and the functional consequences of even small surgical inaccuracies.

Matthew Marquardt, the study’s corresponding author and a third-year medical student at Ohio State, notes that this is the first study to specifically evaluate the impact of 3D modeling on cancer control outcomes, rather than solely on surgical feasibility or workflow.

“This research shows that 3D modeling doesn’t just help surgeons plan. It can directly improve oncological outcomes,” Marquardt says. “That’s an important step toward broader adoption.”

Broader implications for digital surgery

While the current study focused on head and neck cancers, the implications extend beyond this specialty. Personalized 3D models could also enhance precision in other surgical domains where bone and soft tissue intersect, such as orthopedics, maxillofacial surgery and complex reconstructive procedures.

The researchers emphasize that wider implementation of this technology could help standardize high-precision surgery across hospitals, not just in specialized centers. “Our long-term goal is to make these tools accessible to more surgeons and patients,” Marquardt adds. “If this technology can be scaled, it has the potential to improve outcomes and quality of life for cancer patients nationwide.”

As digital planning tools become more integrated into clinical workflows, patient-specific 3D modeling exemplifies how data-driven personalization can translate into tangible benefits at the bedside, and on the operating table.

3D-(bio)printing

Earlier this year American researchers created a 3D-printed heart valve from bioresorbable materials that promote tissue regeneration. This invention means that the 3D-printed implant from bioresorbable materials ensures that the body's own heart valves are regenerated. This means that the patient will probably not need additional surgeries in the future.