Researchers at the Institute of Industrial Science, The University of Tokyo have demonstrated how 3D-printing technology can significantly improve the effectiveness of microneedle array patches (MAPs) for vaccine delivery. By redesigning the structure of the patch using a 3D-printed backing layer, the team achieved higher viral retention and stronger immune responses in preclinical studies.

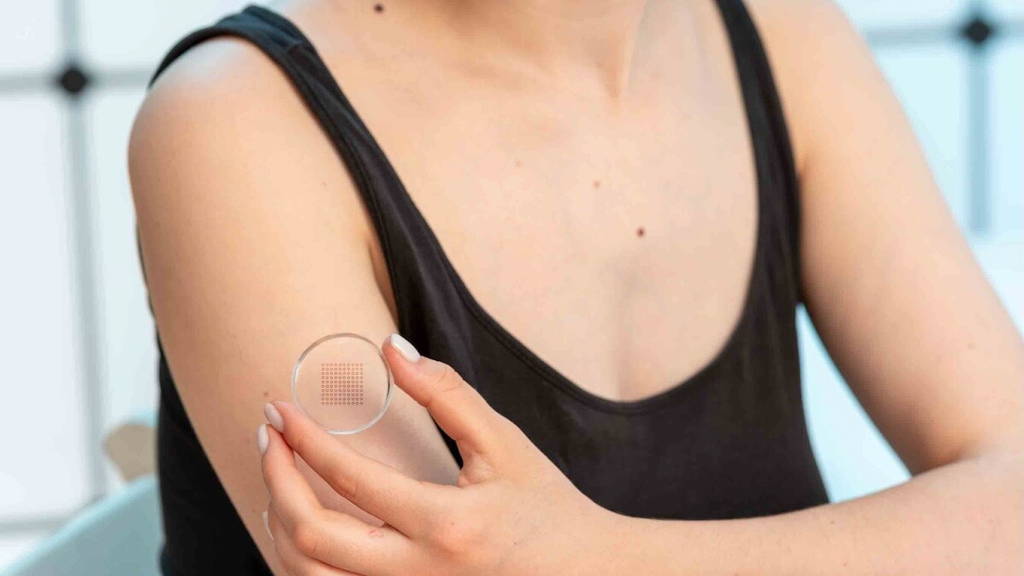

Microneedle patches are widely seen as a promising alternative to conventional injections. They consist of arrays of microscopic, dissolvable needles that painlessly penetrate the outer layer of the skin and release a vaccine. MAPs can be self-administered, do not require trained medical staff and are often more stable at room temperature. These are features that could greatly accelerate mass immunization, particularly during pandemics or in regions with limited healthcare infrastructure.

Overcoming limitations

Despite their promise, delivering live virus vaccines via MAPs presents technical challenges. During fabrication, not all of the viral dose is transferred into the needles, and part of the virus can lose viability as the patch dries. This reduces the effective dose delivered to the patient.

To address this, the Tokyo-based researchers developed a novel “pillar-guided” MAP design. Using 3D-printing, they created a backing layer containing an array of tiny plastic pillars. This structure is inserted into the mold during fabrication, allowing the viral solution to form dissolvable microneedles specifically at the tips of the pillars. The findings are published in Scientific Reports.

“MAPs are typically made by pouring a viral solution into a mold and letting it dry into needle shapes,” explains lead author Kotaro Shobayashi. “With the pillar-guided design, we can better control where the vaccine concentrates and how the needles are formed.”

Stronger immune response

According to senior author Beomjoon Kim, the redesigned structure significantly reduced drying time. This proved critical, as faster drying preserved a larger proportion of live virus within the microneedles. Laboratory tests showed that pillar-guided MAPs retained more viable virus than conventional patches.

The team then evaluated vaccine performance in mice. Animals vaccinated using the pillar-guided MAPs developed robust, virus-specific immune responses and were protected against lethal SARS-CoV-2 infection. These results indicate that the improved fabrication method translates directly into better immunogenicity and protection.

“Our findings show that pillar-guided MAPs are a promising platform for delivering virus vaccines,” says Shobayashi. “They combine efficient delivery with the practical advantages of microneedle patches.”

Implications for global vaccination strategies

The study highlights how advanced manufacturing techniques such as 3D-printing can enhance not only medical devices but also biological performance. By improving vaccine stability and delivery, pillar-guided MAPs could help expand access to effective immunization.

This approach may be particularly valuable in low-resource settings, where cold-chain logistics are a major barrier. The researchers note that live virus vaccines delivered via MAPs remain stable at room temperature, reducing dependence on refrigeration.

While the current study focused on SARS-CoV-2 in animal models, the underlying technology could be adapted for other viral vaccines. As researchers continue to refine microneedle platforms, 3D-printed enhancements like these may play a growing role in future pandemic preparedness and routine vaccination programs.